Combustion Gas

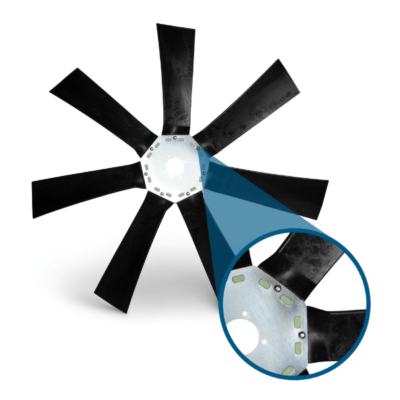

Stainless steel fan impellers deliver the perfect solution for corrosive, high-temperature environments such as combustion flues. Gases can create sulphuric acid, sodium, potassium and chlorine compounds each capable of damaging mechanical equipment. Health and safety demands costly scheduled maintenance however by designing impellers using 304 and 316 stainless steels, Truflo helps minimize equipment downtime and associated costs.

Features & Benefits

- Anti-corrosion

- Very high temperatures

- Twin-riveted construction

- High Efficiency, Low Noise

- Available in 12in (300mm) to 118in (3000mm) diameters

Sample Configurations

Power Plant

- High temperature

- Corrosion resistant 316 stainless steel

- High flow, high pressure, low noise

Transferring combustion gases for subsequent processing (e.g. desulphurization) requires high-flow, high-pressure fans able to withstand very high temperatures and a wide range of corrosive elements including sodium compounds and acids. Truflo stainless steel fan impellers help to extend fan life and limit costly downtime. Finely balanced, sickle-shaped fan blades deliver the flow and pressure requirements whilst helping to minimize noise.

Smelting Plant

- Segmented fan design for strength

- High strength materials

- Corrosion resistance

Noxious and highly corrosive hot gases produce in smelting plants must be extracted quickly and safely to protect the workforce and satisfy environmental regulations. Harsh elements such as sulfur dioxide produce harsh acids and so Truflo designs fans using suitable materials and finishes to ensure reliability and productivity of the plant, through minimal downtime.

Truflo Technology

Truflo Fan Selection Software

-

- Online & accessible from any device

- No applications to download or update

- Provides 3D CAD Models

- Exports to Excel, PDF or KULI formats

- Save your personalized fan selections

- 2D Drawing downloads

Blade & Fan Technologies

Our range of blade profiles, materials and construction options provides a customized approach to create a solution that is perfect for your unique application.

Custom Testing & Design

Providing our customers opportunities to design and test specific fans through tip profiling, various mounting options, wind tunnel testing and even competitor benchmarking. Our on-site fan testing and analysis ensures that Truflo’s fan test data is accurate and repeatable. Our wind tunnel can accommodate some of the largest fans, up to 84in (2100mm).