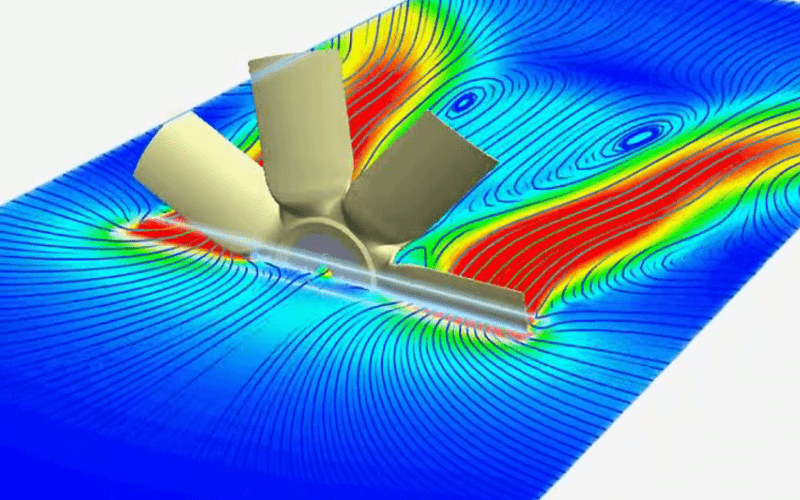

Providing innovative and reliable fan products globally for engine cooling since 1962. Our engineers work hard to achieve your vision from design to production. Truflo has the technology and capability to provide a range of fan solutions from a high volume production one-piece molded fan, maximum optimization in a hybrid fan, and durable metal fan options. Manufacturing facilities in the United States, United Kingdom, and China to maximize distribution flexibility.

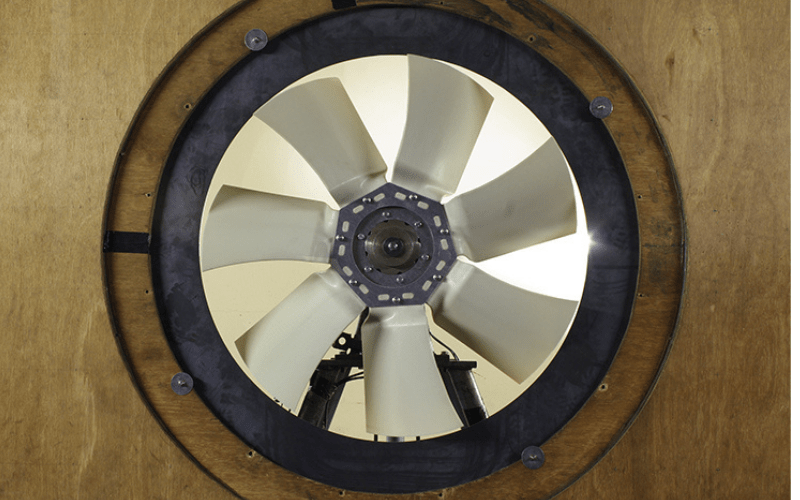

Hybrid Fans

- Ultimate design optimization for your cooling and ventilation needs

- Easily configure fan options to meet your specifications (low noise, high efficiency, etc.)

- Lightweight design

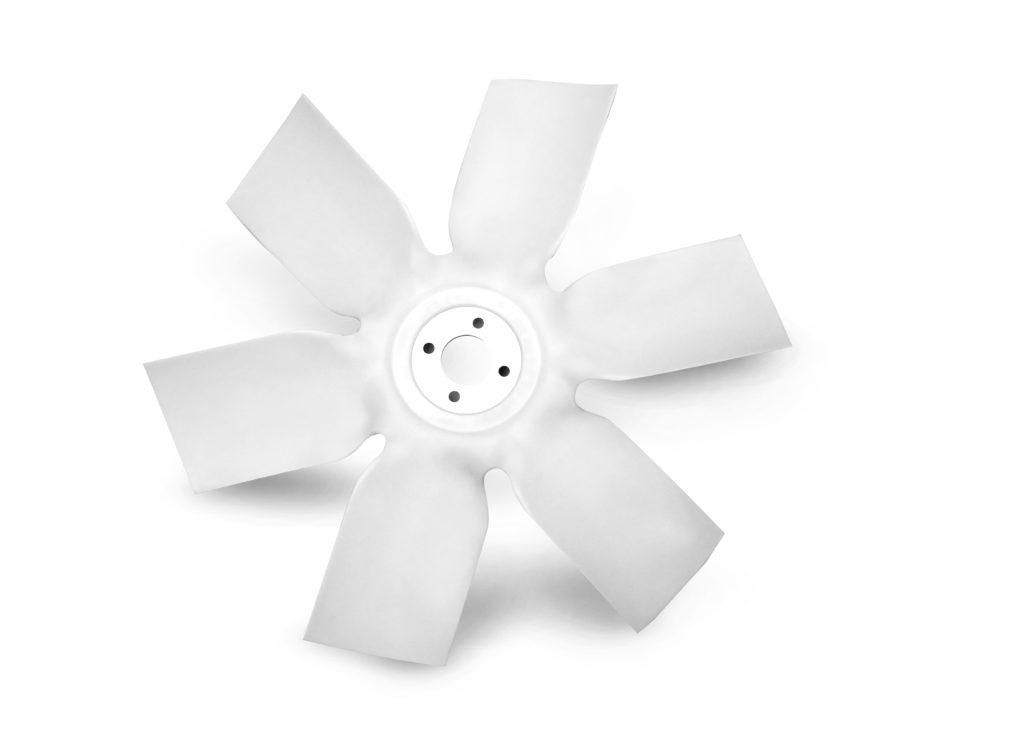

One-Piece Molded

- The most cost-effective fan design solution available

- Helps engineers to meet strict noise and efficiency regulations

- Powerful yet compact and available up to 40in (1000mm) diameter

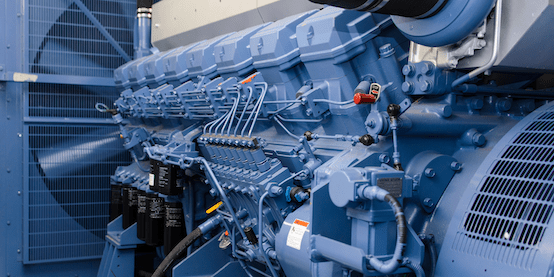

Spider Metal Fans

- For demanding applications up to 70in (1800mm) diameter

- Suitable for extreme temperatures

- Available in a variety of metals including Aluminum and Stainless Steel

Segmented Metal

- Synonymous with large engine applications including mining equipment and power generation

- Available up to 118in (3000mm) diameter

- Robust and durable, designed for the life of the application

An experienced global supplier of high performance fans for the most challenging applications

About Truflo: A Leader in Cooling Fan Systems

Truflo has been developing industrial cooling fan products globally since 1962. Our engineers strive to help you achieve products that are ideal for your needs, from design to production. A division of Phillips & Temro Industries, Truflo has the manufacturing technology and capabilities to provide a wide range of cooling solutions.

Design

- Engineering and project management support

- Online fan selection tool

- 3D CAD models & 2D drawings

- Data export files – PDF, Excel, & KULI

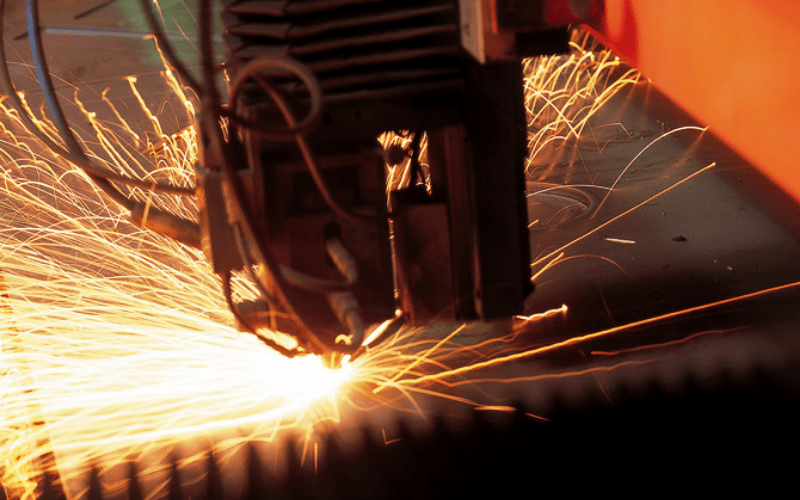

Manufacturing

- Design and Validation services ensure your fan meets your requirements

- Manufacturing in the USA, UK, & China to IATF16949 ISO9001 and ISO14001

- Produced to tight dimensional tolerances for reliable, repeatable performance

Global Manufacturing & Distribution

Station Street Tipton

West Midlands DY4 8UG United Kingdom

Local: +44 (0) 121 557 4101

Email: sales@trulo-airmovement.com

9700 West 74th Street

Eden Prairie, MN 55344

Local: (952) 941-9700

Toll Free: 1-800-328-6108

Email: sales@phillipsandtemro.com

10 Lianzhong Road Automotive Industrial Park

Yizheng, Jiangsu Province P.R. China 211400

Local: +86 514 835 82600