Fan Specifications

Reach maximum performance with Truflo Fans.

Popular Market Applications

The Truflo Technology

Request Information

Do you have a question about a product? Interested in learning more? Select which area you are interested in below then complete the short contact form and we will be in touch.

A leader in engine cooling fans for agriculture, construction, mining, power generation and off-road applications, Truflo designs and manufactures a range of One-Piece molded fans, to help thermal engineers optimize their designs and satisfy emission and noise regulations without compromising on airflow performance.

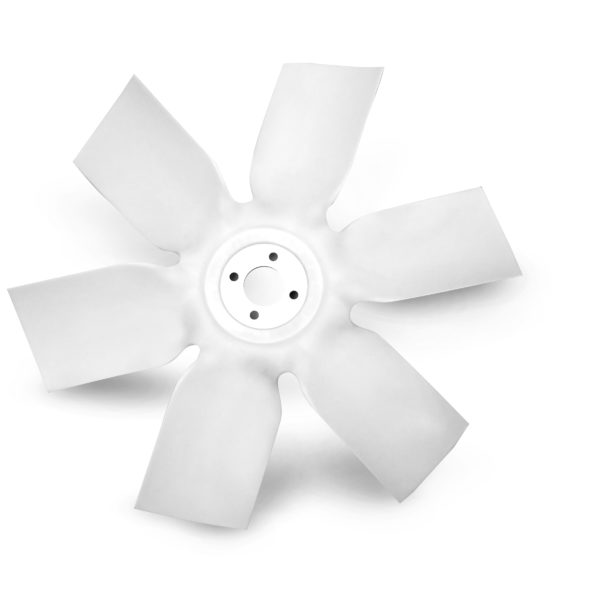

Truflo’s One-Piece molded fans 12-40in (300-1000mm) include the cost effective SAP20, the super quiet SDS39 and the highly efficient SET40. The most cost-effective range of engine cooling fans available. Each is available in standard or reverse airflow direction.

| Diameters | Blade Count | Blade Profiles | Blade Angles | Blade Materials |

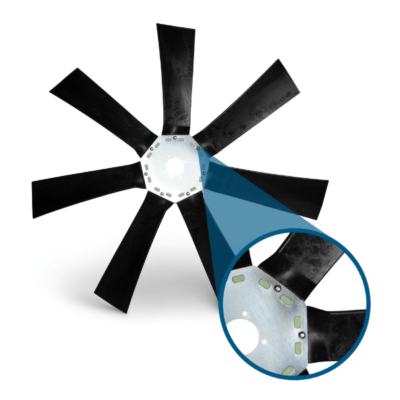

| Min: 12in (300mm) Max: 40in (1000mm) | 6, 7, or 9 Blades | Sickle Blade Parallel Blade Tapered Blade Learn More | 26° and 32° | Glass-filled Polyamide Polypropylene Anti-static Anti-microbial Bespoke colors available |

Designed to fit your custom needs for accurate pressure and airflow down to the individual degree. Coupled with our various blade designs will create a solution that is perfect for your unique application.

AMCA 210 Wind Tunnel – One of the largest, accommodating fans up to 84in (2100mm) in diameter, ensuring Truflo’s fan test data is accurate and reliable.

Competitor Benchmarking – Perform back-to-back testing of fans for realistic performance comparisons.

Design Customization – Fan configurations matched to your precise duty point. Branded fans can include your corporate logos and colors. Bespoke fan blade profiling. Incorporate any fan mounting pattern or choose from a wide range of shaft hub adaptors. Fan strain testing available on/off site, including AMCA210 Wind Tunnel validation.